Für die Creality 3D Drucker Ender 3 V2 und Ender S1 gibt es die alternative Firmware von Mrisoc, die auf der Open-Source Firmware Marlin basiert und speziell für Ender 3 V2 und S1, angepasst und optimiert ist.

NEW YEAR 2023 – Ender 3 V2/S1 Firmware 20221222

Firmware Download: https://github.com/mriscoc/Ender3V2S1/releases/tag/20221222

What’s new in this release

- Support for Input Shaping in the Special Configuration repository

- Add MPC as default for precompiled version if program memory space allows it

- TMC Trinamic driver current editor menu when it is supported (not for standalone)

- Menu item for enable/disable Adaptive Step Smoothing when it is supported

- Reset Print stats confirmation

- Show message when is not possible to park head on pause

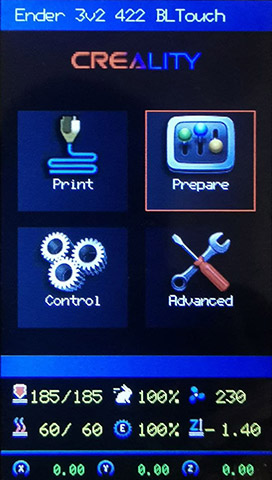

- Preheat hotend menu for Prepare/Filament management menu

- Mesh Leveling progress viewer

- Added PETG Preheat in precompiled versions (Current source supports 10 material preheats)

- And many improvements and fixes

From Marlin 2.1.2

- More SCURVE cycles on unoptimized cortex-m0 (#24955)

- Fix G-code resend race condition

- G30 move to logical XY (#24953)

- and many more fixes from latest bugfix 2.1.x

This firmware is based on Marlin, has been optimized and has enhancements for the Creality Ender 3 V2/S1 printer. This is an universal firmware that can be used in both RET6 and RCT6 STM32FX chips that have 256k or 512k Flash memory.

Requirements

In order to use this firmware, your printer must meet the following requirements:

- A compatible control board: Creality 4.2.2, 4.2.3, 4.2.7, V24S1_301F1, V24S1_301F4 or SKR Mini E3_V3 for Ender series printers with a STM32 SoC.

- A DWIN or DACAI color screen with encoder knob. Touch screens are not supported.

You can modify your printer to meet these requirements.

Versions

- Ender 3v2 MM: if you have the Ender 3v2 near to stock then use this version (Manual Mesh).

- Ender 3v2 BLT: use this version if you installed a CR/3D/BLTouch level sensor in the Ender 3v2.

- Ender 3S1: use this version if you have an Ender 3S1 printer

UBL versions

Binaries with UBL in their filename have support for Marlin Unified Bed Leveling, this system is similar to the bilinear leveling but with a few extra features to provide users with more control. There are multiple guides on the web about UBL, we recommend reading about it before using this new leveling system.

- https://marlinfw.org/docs/features/unified_bed_leveling.html

- https://all3dp.com/2/marlin-ubl-unified-bed-levelin-simply-explained/

- https://www.3dmakerengineering.com/blogs/3d-printing/unified-bed-leveling-marlin

- https://hackaday.com/2022/01/14/3d-printering-getting-started-with-universal-bed-leveling/

Model Predictive Temperature Control (MPC)

From this version MPC is being incorporated in all versions. MPC has proven to be a better algorithm for keeping the nozzle temperature stable, and is also very useful for high power heaters.

You can download the latest binaries from the assets at the bottom of

the release page.

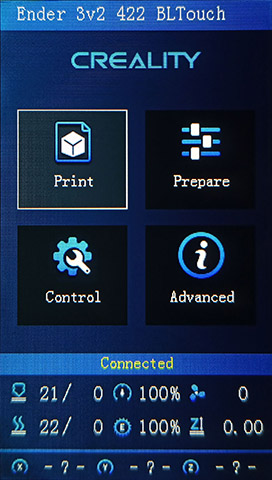

To know if you have the last release go to the info page in the display of

your printer and compare the release build date with the name of the binary

file. The filename follows the convention:

Ender3V2-422-MM-YYYYMMDD.bin

Where YYYYMMDD indicates the date of the build. 422 refers to the mainboard

version 4.2.2, 423 refers to the mainboard version 4.2.3, and 427 is for the 4.2.7 mainboard version, if you got

a 4.3.1 board use the 422 version. SKRMINI version is currently for the

BTT SKR Mini E3 V3 board (needs a screen adapter).

For example, if you want a firmware for your Ender-3 V2 printer with a control

board version 4.2.2, CRTouch and support for UBL, you should download the file:

Ender3V2-422-BLTUBL-YYYYMMDD.bin

Firmware features

- Universal RCT6/RET6 Ender 3 V2/S1 Support

- DWIN / DACAI screens support

- Improved support for Manual Mesh and CR/3D/BLTouch

- User configurable power lost recovery enabler

- Manual and assisted bed tramming

- Tramming Wizard for BL/3D/CRTouch versions

- Long filename support with scroll

- Axis value in dash board shows actual position of the axes, including Z leveling

- Baby Z-Stepping

- Firmware Retract

- Advanced pause feature

- Configurable park-head position (default x=240 y=220)

- Filament change support

- Filament management (load/unload/park head) in prepare menu

- Print Flow on Motion and Tune menu

- Home axis after motor disabling

- Fastest Z feed rate

- Live move for all motors but extruder

- Support for S-curve Acceleration

- Reboot printer item on control menu

- Increase extruder feed rate limit to 150 for BMG users

- Allows to invert direction of the extruder on Motion menu

- Support for BTT Smart filament sensor

- Selectable runout filament sensor active state (LOW/HIGH/MOTION)

- Editable runout distance

- Support for memory card extensions via Media Update (auto-mount) Enable/Disable menu item

- PID popup with temperature plot

- Lock screen

- Editable physical dimensions

- Mesh viewer and editor

- Custom pre-heat

- Enable/disable beeps sound

- View of embedded thumbnail g-code (use this guide)

- New print done screen

- Two decimal positions for axis coordinates value

- New Z-Offset wizard

- New PID settings menus

- PID moves the head to the center for more accuracy

- Leveling bed temperature linked to bed PID temperature

- Editable extrude minimum temperature

- Brightness settings on tune menu

- Turn off the backlight of the lcd in the tune menu

- New status line system, allows the scroll of large messages

- Home submenu with individual axis homing

- Enabled user setting for 115200 bauds (Creality Box compatibility)

- Head parking before recovery after power failure

- Offset icon changes to show leveling status

- Live end-stop diagnostic page

- Move bed to front after cancelling a print.

- Editable firmware retracts settings for Tune and filament settings menu

- Print Statistics page accessible from the Advanced Settings menu

- Toolbar with 11 configurable shortcuts actions.

- Support in source code of control menus for LED lights as the Neopixel

- Support up to 10 Preheat settings (needs own compile)

- Support for Model predictive temperature control „MPC“ (needs own compile)

Manual mesh

- Assisted manual bed tramming

- Assisted manual mesh leveling menu

- Selectable mesh points from 2×2 to 9×9

- Mesh viewer

- Persistent Z-offset

- Move Z to 0 and disable motors option

- Mesh editor for fine tuning

- Allows to set the Z height after Z home

CR/3D/BLTouch

- Safe Probe Z-Homing

- Bed auto level

- High speed probe

- Retry bed level on error

- Mesh viewer

- Assisted tramming

- Selectable mesh points from 2×2 to 9×9

- Allows the user to cancel an auto leveling process

- Increase Max Probe Offset and Probing Margin to 60 mm

- M48 Probe Test to Probe Settings menu

- Probe Stow/Deploy in Probe Settings menu

- Option to disable HS mode for better compatibility with CRTouch

- Option to change the Z Probe feed rate

- Configurable Bed auto leveling temperature

- Mesh editor for fine tuning

- Automatic maximize leveling area

- Automatic center leveling area

- Editable multiple probing

G-Codes enhanced support

- Filament Load Unload G-codes (M701/M702)

- Support for M600 filament change

- Support for G-code M117 messages

- Enable M575 change baud rate by G-code

- Extended M75 with filename support, use M75 {{ event.name }} in g-code script

- Enable ARC and ‚P‘ parameter to specify complete circles (G2/G3)

- G35 support

- M155 Geometry report

- Native support of marlin brightness and M256 g-code

Support for special nonstandard custom C G-Codes

- C10 marks a G-code file as a configuration file to avoid confirm to print and print done dialogs.

- Implemented C11 En Rn Gn Bn gcode for colorize UI elements

- C108: Cancels screens waiting for user simple confirmation

- C29 F### B### L### R### N# T#: Mesh insets, amount of grid points and bed temperature of the mesh leveling

- C100 X### Y###: to sets minimum limits

- C101 X### Y### z###: sets maximum limits

- C102 X### Y###: sets bed size

- C104 U1 T###: unlocks the hotend maximum temperature to ###°C (CAUTION)

- C115: Shows ProUI details

- C125 X### Y### z###: sets the park position

- C412 M#: sets run-out sensor active state (M0:LOW, M1:HIGH, M2:MOTION)

- C510: locks/unlocks the screen (C510 U1 to unlock)

- C562 E#: inverts the Extruder (E1 to invert)

- C810: sets up the toolbar shortcuts

- C851 S#### [Z###] Mn: sets probe Z feed rate (S) and set Multiple probing (Mn>1) or disables it (M0), in manual mesh

version, Z parameter can be used to set a manual Z-offset.

Advanced settings menu

- Advanced mesh leveling editing features

- Probe offsets menu (BLTouch version)

- Customizable park-head position

- Customizable bed size and z heigh up to 999 x 999 x 999

- Launch PID for nozzle and bed with graphical feedback

- Filament run-out sensor with active state setup (LOW/HIGH)

- Filament load and unload lengths menu items in run-out menu

- Power-loss recovery enable/disable option

- LCD Brightness control

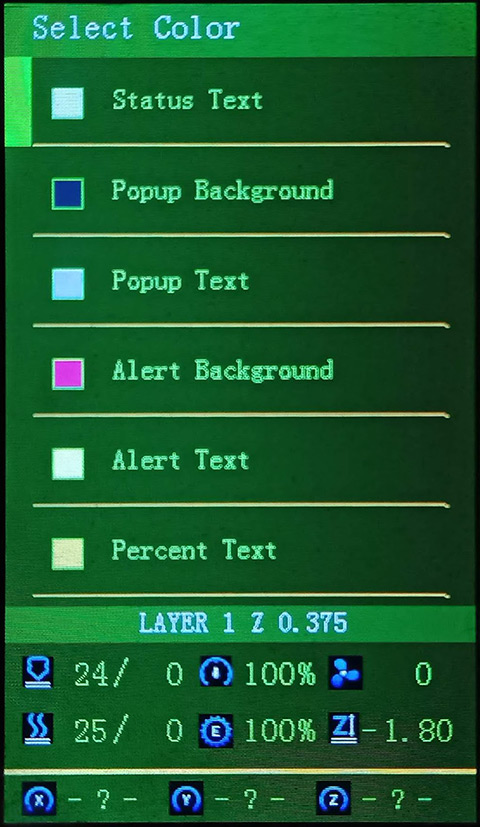

- Select Color Sub Menu

- Beep/Sound enable/disable option

- Selectable mesh point (BLTouch version)

- Media Update (auto-mount) for memory card extensions support

- Lock screen

- End-stop diagnostics

Special Octoprint / Host print support

- High speed (250000 baud) serial communication

- In screen control of host printing (M73, M75-M77)

- Display messages on status line (M117)

- Color change of UI elements for visual status report (C11)

- Binary file transfer for remote firmware upgrade

- List binary (.bin) files (M20) for flash firmware support with BFT

- Arc Welder Octoprint plugin support

- EEPROM Editor Octoprint plugin support

- Host action commands for filament runout

- Emergency Parser active

- Advanced OK

Octoprint bed visualizer support

Display enhancements

- Extended DWIN library

- Enhanced status messages

- Improved status bar with temperature, flow, fan, z-offset and xyz positions

- PID auto tune progress on display with plot

- Leveling progress on display

- Boot screen for M997

- Transparent icons for better color theme adaptability

- New print g-code preview

- New print done screen

A lot of additions and fixes from Bugfix development branch

Interessiert in verschiedenste IT Themen, schreibe ich in diesem Blog über Software, Hardware, Smart Home, Games und vieles mehr. Ich berichte z.B. über die Installation und Konfiguration von Software als auch von Problemen mit dieser. News sind ebenso spannend, sodass ich auch über Updates, Releases und Neuigkeiten aus der IT berichte. Letztendlich nutze ich Taste-of-IT als eigene Dokumentation und Anlaufstelle bei wiederkehrenden Themen. Ich hoffe ich kann dich ebenso informieren und bei Problemen eine schnelle Lösung anbieten. Wer meinen Aufwand unterstützen möchte, kann gerne eine Tasse oder Pod Kaffe per PayPal spenden – vielen Dank.